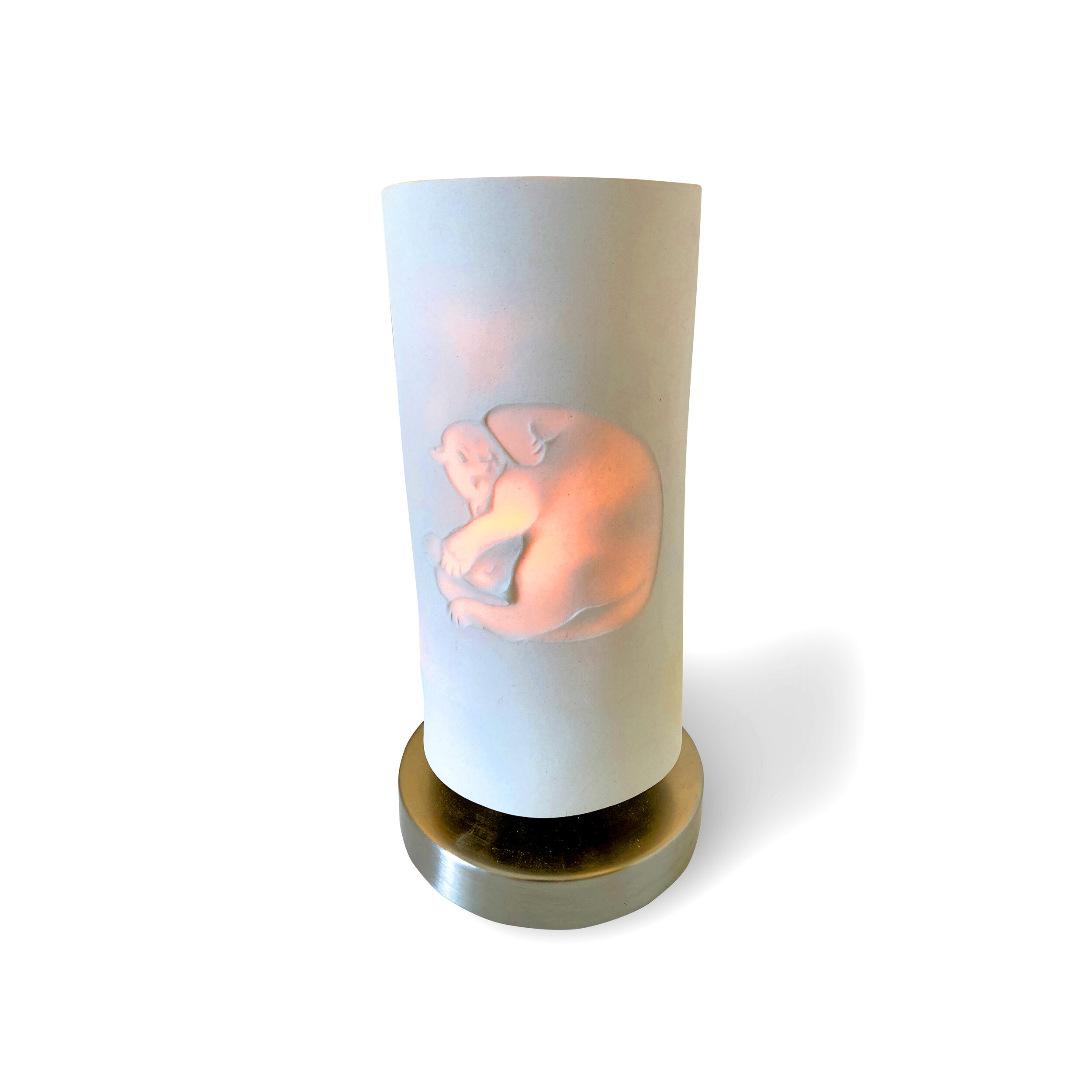

George

LITHOPHANE PORCELAIN LAMP

Image created on thin porcelain then rolled into a tube

Diameter 100mm x Height 250mm

Using a white clay similar to porcelain, Tom mixes the clay with paper and adjusts the moisture levels at the same time. Each piece is then built, mostly from multiple individual components. They are then set out to dry to a firm state. At this stage final trimming and finishing takes place after which they are set out to dry over several days until ready to go in the kiln for bisque.

A bisque fireing is over 24 hours and reaches a temp of 1000 degrees then takes another 2 days to cool before the kiln is emptied. Each piece is then named and numbered before glaze is applied and returned to the kiln and taken to 1170 degrees where the glazes melt.

When they come out they are checked for quality and discard if not up to standard. Tom’s designs tend to be high risk and I encounter about 25% down graded.